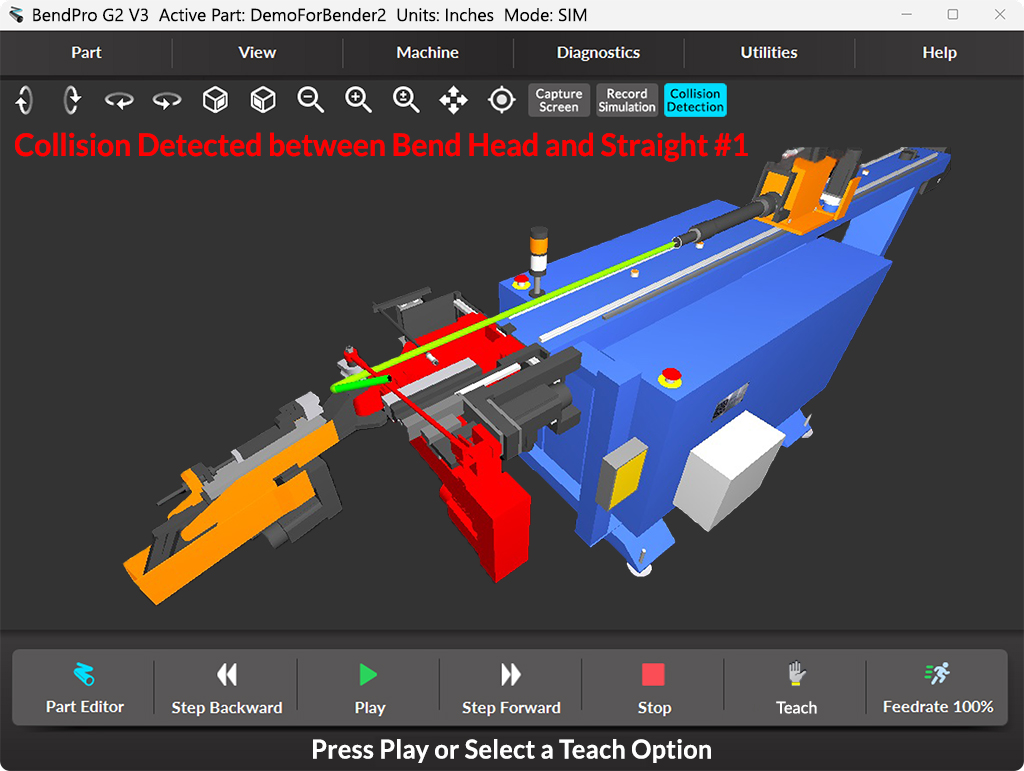

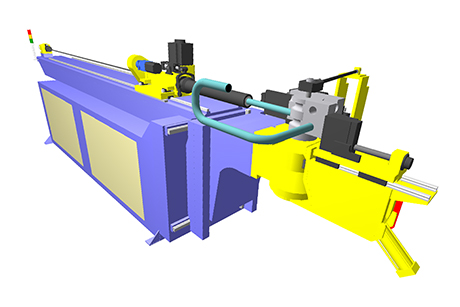

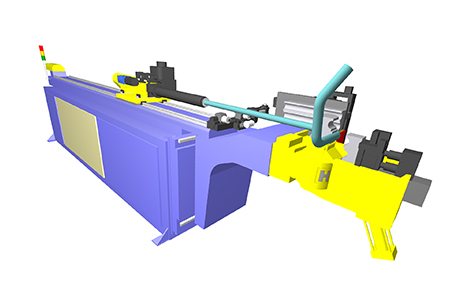

This powerful software option simulates the bending process to detect collisions between the tube, bending machine, and bend tooling.

SIM can also be used to determine optimal bending sequences in order to avoid collisions and also reduce cycle times.

In addition, cycle times can be calculated for the purpose of accurately bidding jobs.

The Simulation option does everything that BendPro Office software does with the addition of the following:

When a collision is detected, the simulation will pause and highlight the interference points on the tube or bender. Interference problems can be quickly corrected using the various tools within BendPro SIM, including automatically reversing the order of the bends or using Virtual Teach Mode to intuitively create optimal machine sequences.

BendPro SIM is designed to simplify and optimize the process of tube bending. The basic process is as follows:

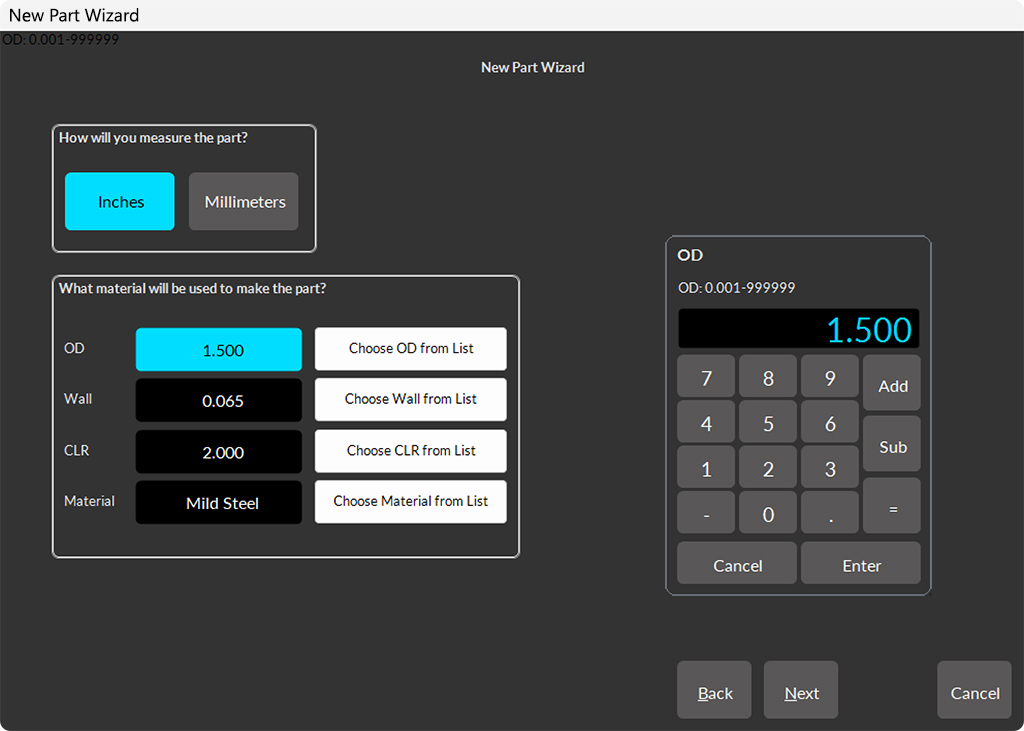

The New Part Wizard walks you through each screen step by step allowing for quick, easy, and error-free creation of new part programs.

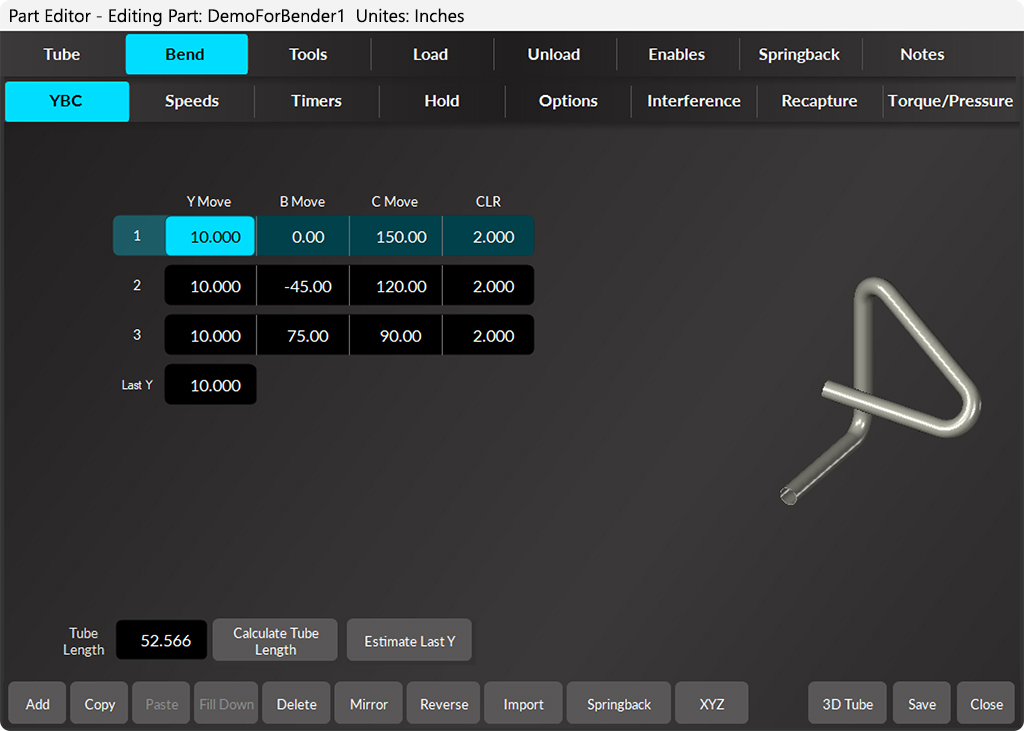

New customers are surprised by how quick and easy it is to program parts in BendPro, especially when compared to other control systems. The Parts Editor is designed to make data entry and editing intuitive and easy.

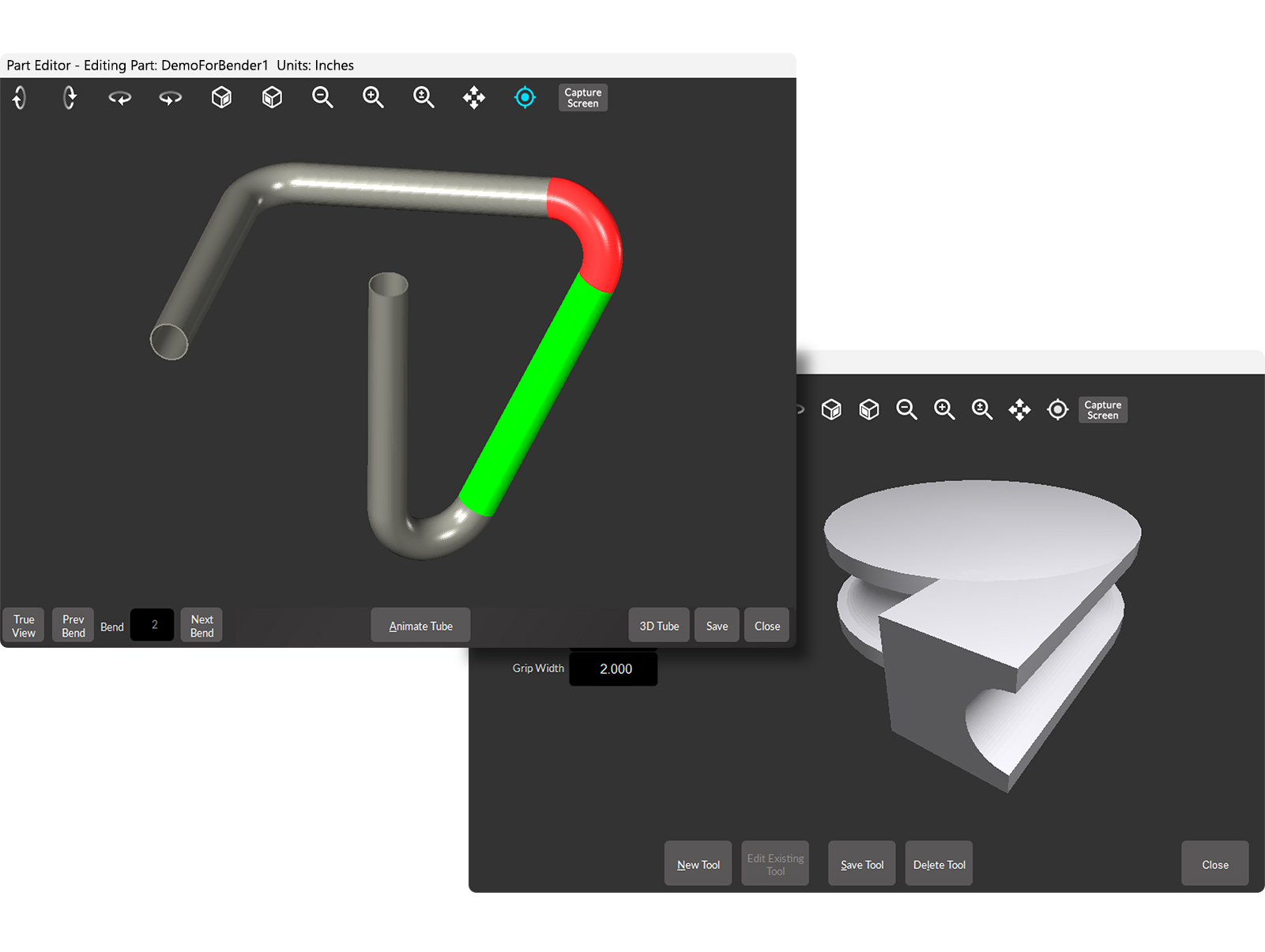

Tubes can be displayed in 3D on the screen for the purpose of verifying the part geometry and the bending orientation. Command buttons are included for rotating, spinning, panning and zooming in or out. Individual bends and straight lengths can be highlighted for review and verification.

The Tube can also be animated to show the bending orientation. And a screen capture button allows copy and paste functions into Windows programs including Outlook and Word, etc.

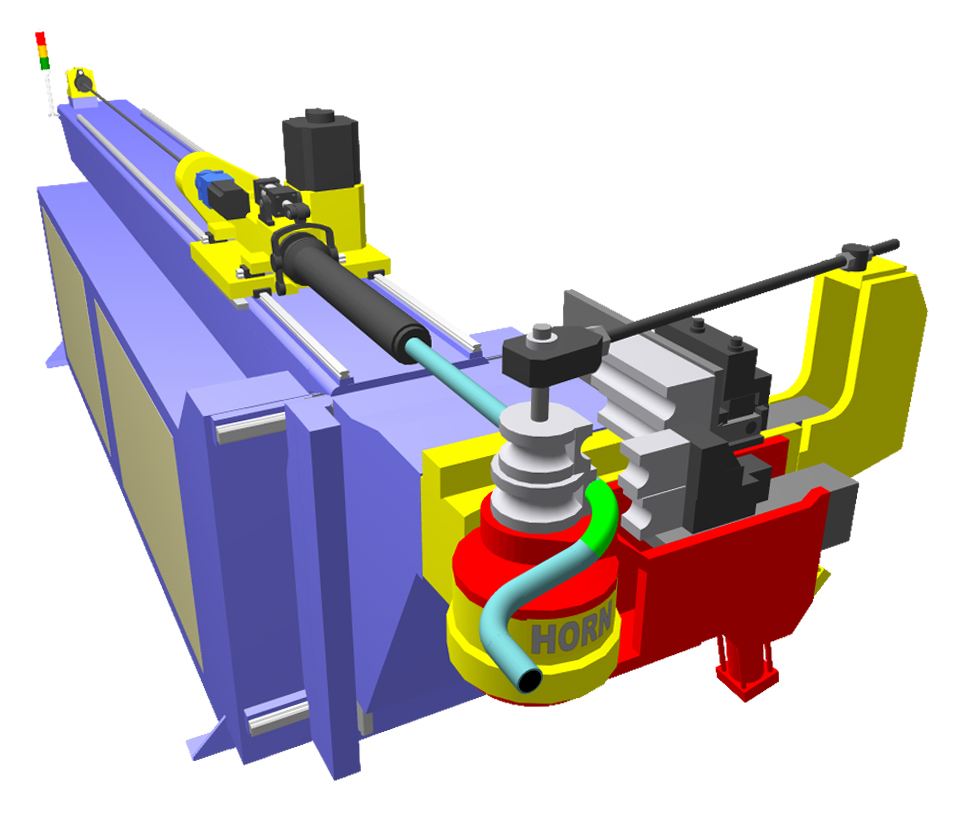

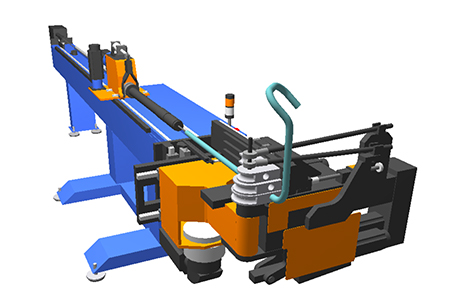

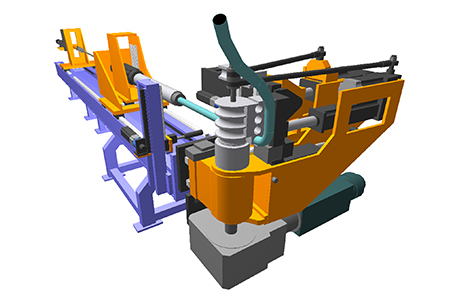

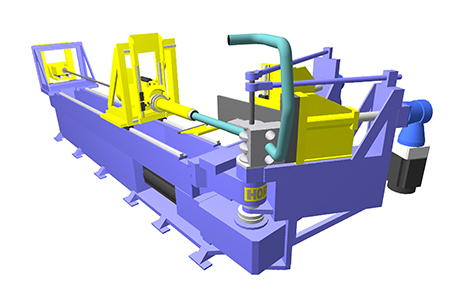

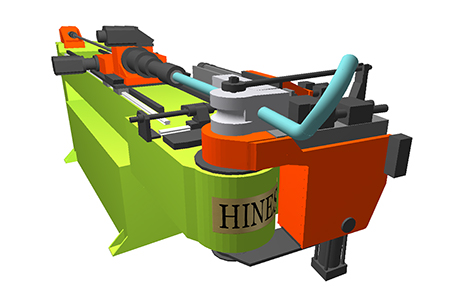

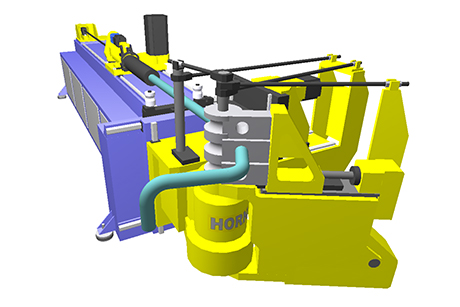

Bend Tools are automatically rendered by the bend simulator software. Custom bend tools and tool sets can also be created using the Tool Editor and stored by part number.

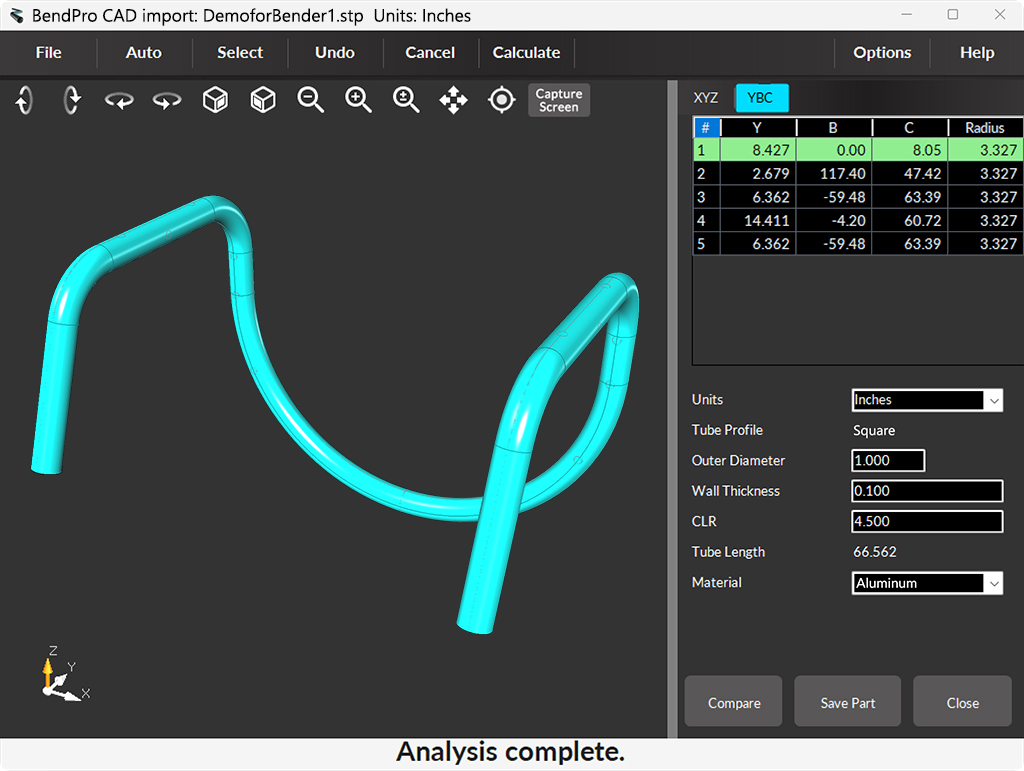

Part files can be imported from CAD files in STEP and IGES formats, or from other bender controls including Eaton Leonard, Adaptive Motion, and Eagle. Office PCs, Excel spreadsheets, measuring machines, Supravision, ShipConstructor, etc., are also supported.

With this option the BendPro software can automatically import tube geometries from virtually any CAD program including SolidWorks, Solid Edge, AutoCAD, Inventor, CATIA, Pro-E, etc.

STEP or IGES files can be imported directly into the BendPro software and automatically translated to true bend data. This makes programming new parts much easier and quicker while reducing data entry mistakes.

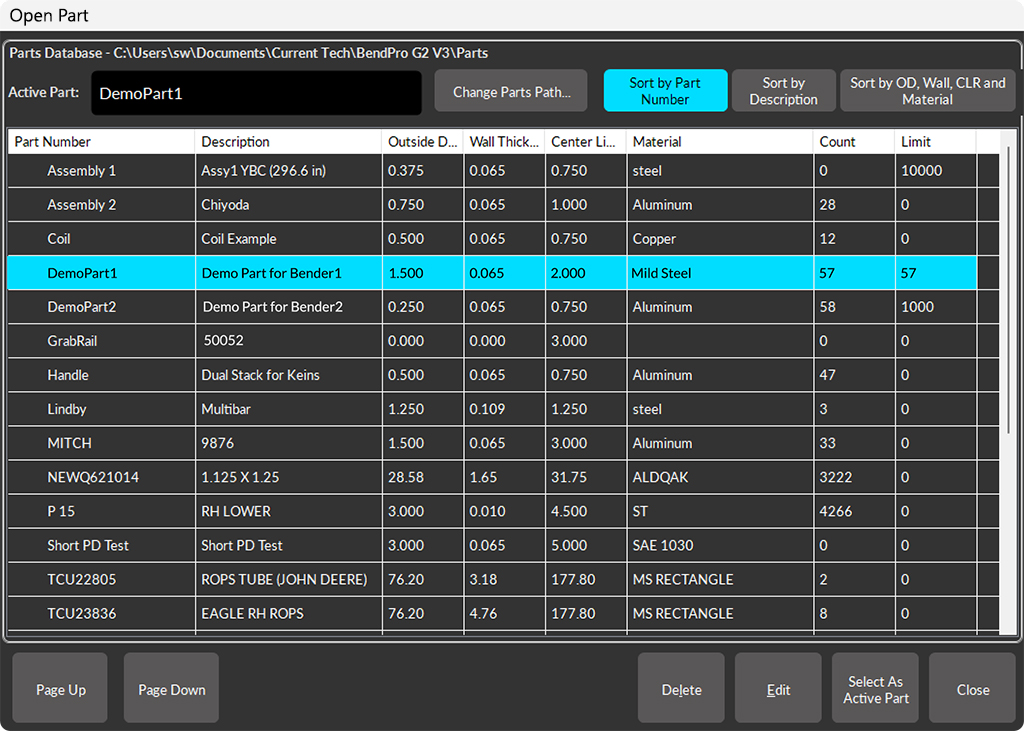

The Parts menu can display and sort all part files based on part number, description, or material parameters. The BendPro software can automatically backup all part files and machine parameters to a local or network drive or to the cloud. There is virtually no limit to the number of part files that can be stored and recalled. Part files can be automatically transferred to the bender by using a network connection or USB flash drive.

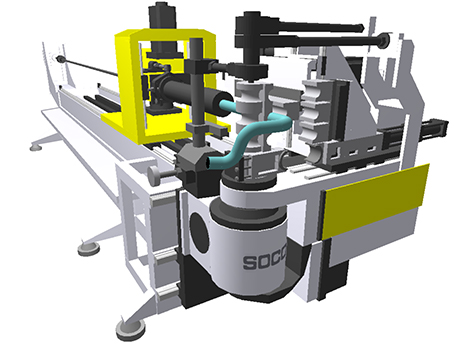

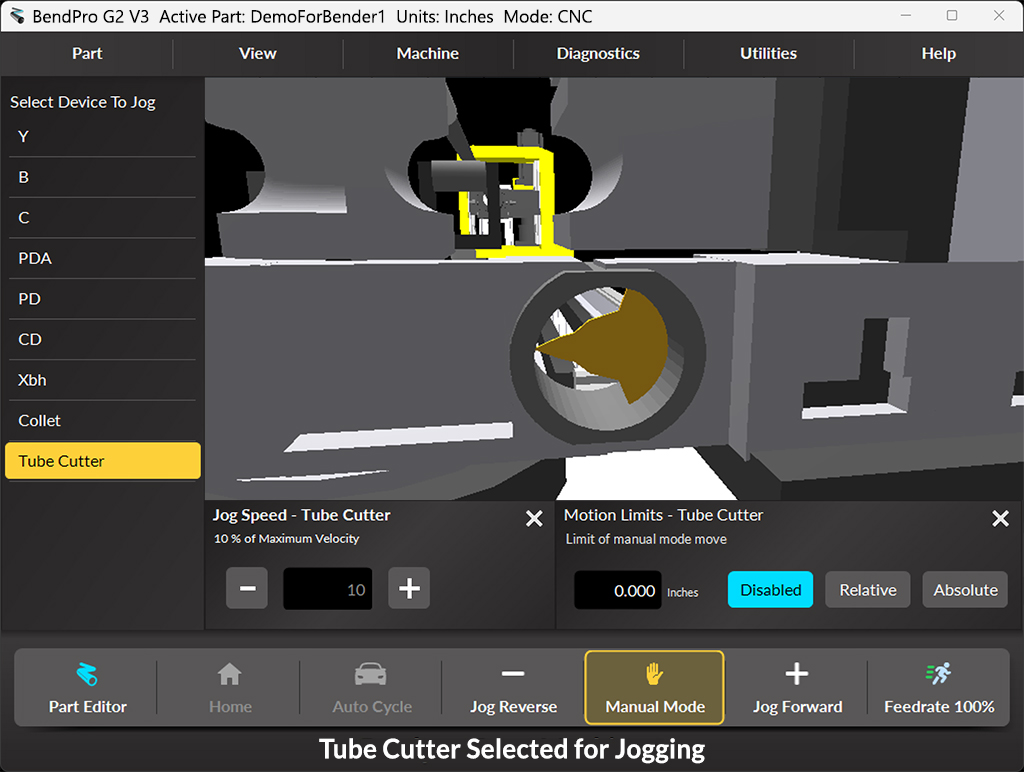

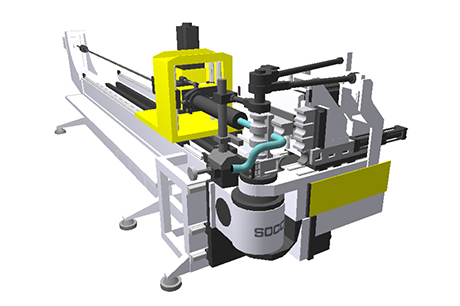

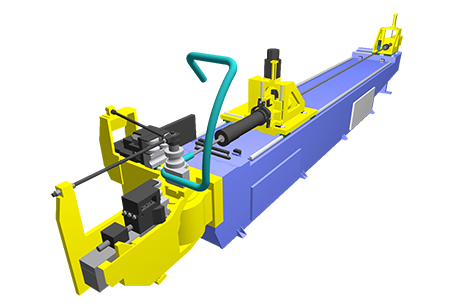

BendPro can even simulate benders with a tube cutter including this SOCO machine.

BendPro can simulate the motion of tube cutters in Manual Jog Mode or Auto Cycle Mode.

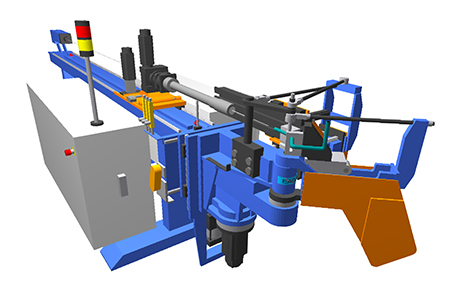

Our library of tube bender models includes machines from these manufacturers:

Addison

Chiyoda

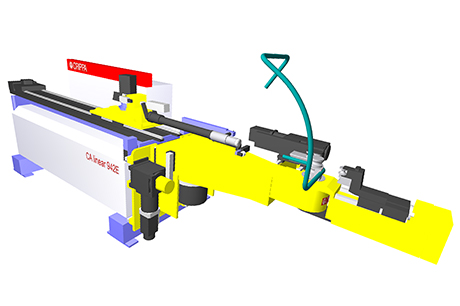

Crippa

CSM

Eagle

Eaton Leonard

Hines Bending Systems

Horn Machine Tools

Keins

Mewag

MiiC

Pedrazzoli

Pines

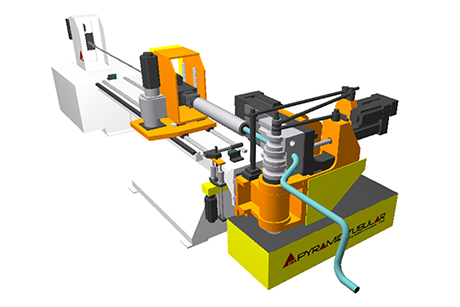

Pyramid Tubular

SOCO

Techno

Tube-Line Technologies

Universal Tool & Engineering

Yes.

Over the years we have created an extensive library of 3D models for various machines. If we don't have a model of your bending machine we will need to create one. This may be subject to an additional cost.