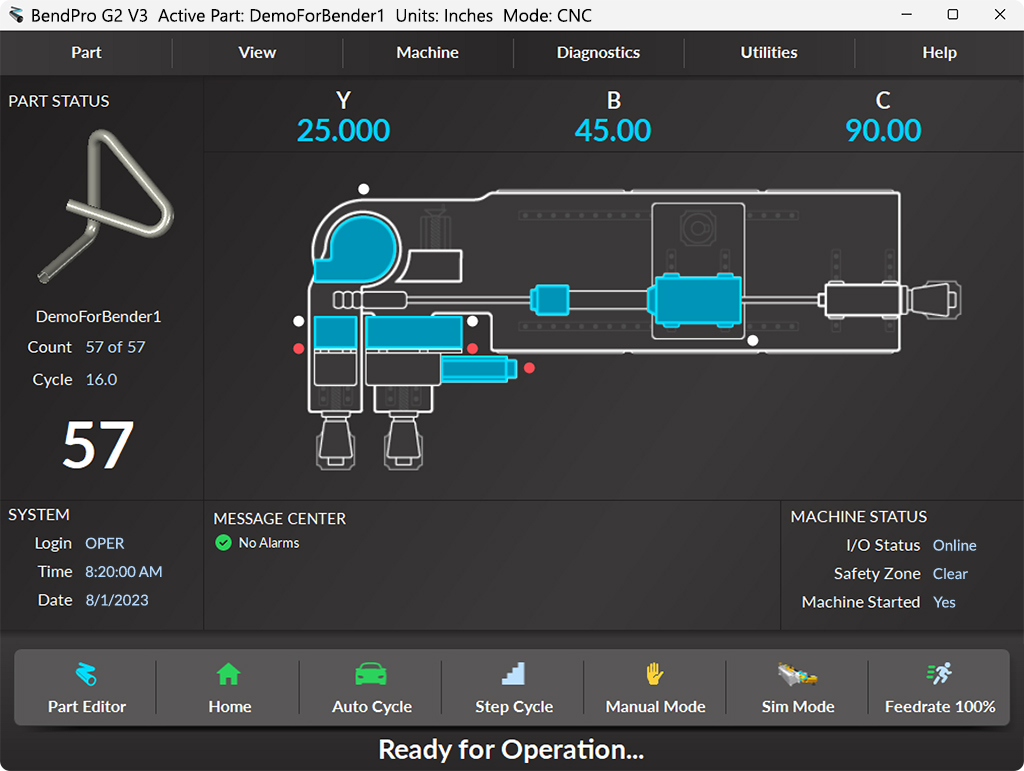

BendPro brings new life and performance to any CNC tube bender and has become the industry standard control system.

Customers tell us it offers the highest level of performance, reliability, and functionality available.

Companies standardize on BendPro because it works with all of their tube bending machines regardless of make and model.

Operators benefit from learning a single control system. Naturally, this reduces training time, down time, and scrapped material while increasing productivity.

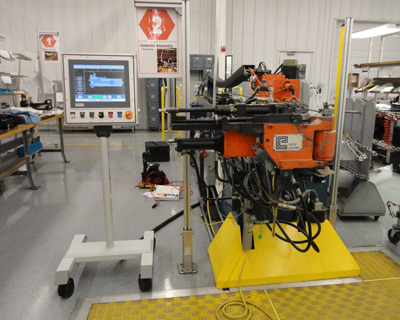

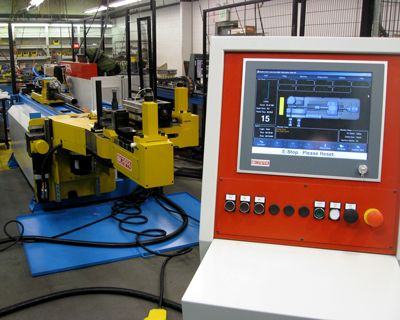

Upgrading your existing bender with BendPro is far less expensive than purchasing a new bender. And you can keep using your existing bending dies.

BendPro can be installed on site at your location; you won’t need to send your bender anywhere. Customers can have their existing benders upgraded with BendPro and also order it with most new benders on the market.

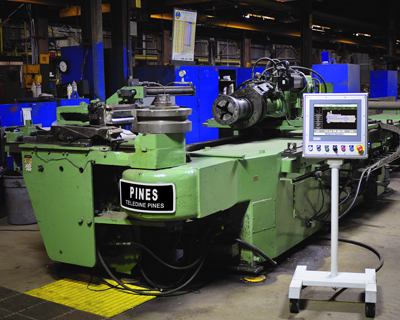

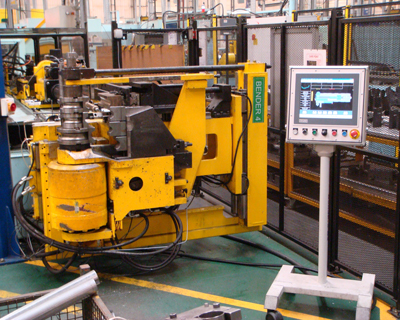

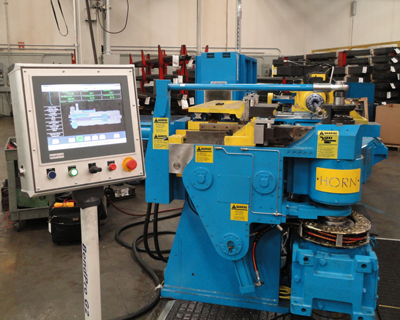

The list of benders supported by BendPro continues to grow and currently includes Addison, Eagle, Eaton Leonard, Pines, CSM, Chiyoda, COMCO, Keins, SOCO, YLM, MiiC, BLM, Pedrazzoli, and others.

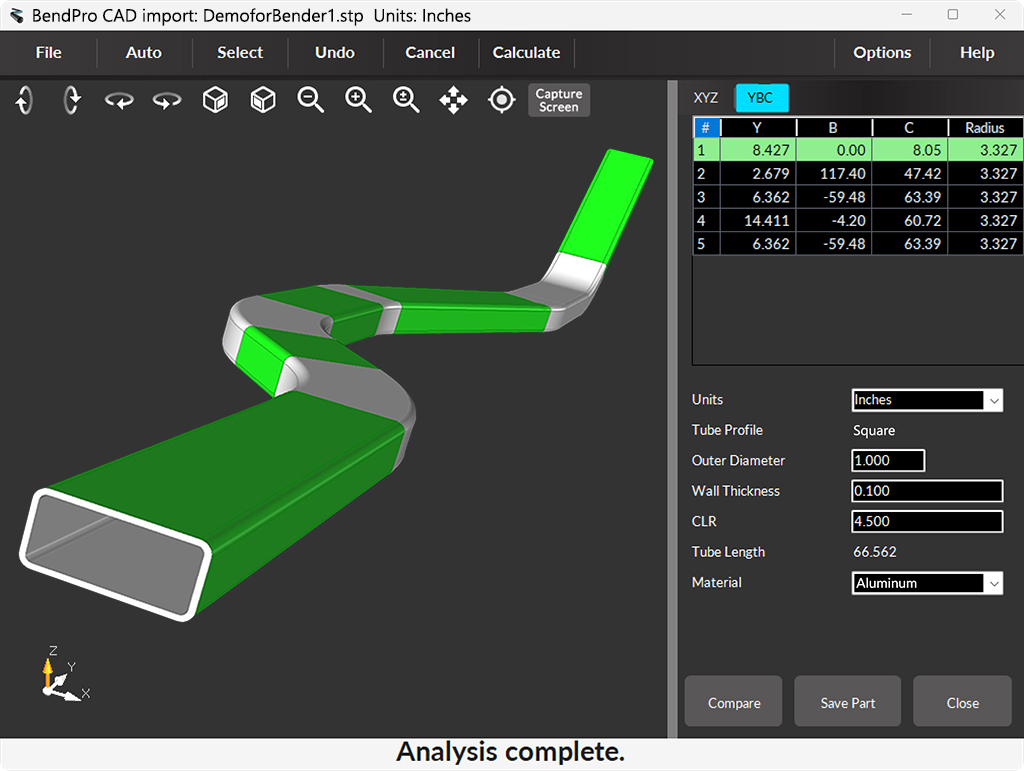

BendPro can import tubes geometries from virtually any CAD program including SolidWorks, Solid Edge, AutoCAD, Inventor, CATIA, Pro-E, etc.

STEP or IGES files can be imported directly into the BendPro software and saved as bender part or Supravision files. This makes programming new parts much easier and quicker while reducing data entry mistakes.

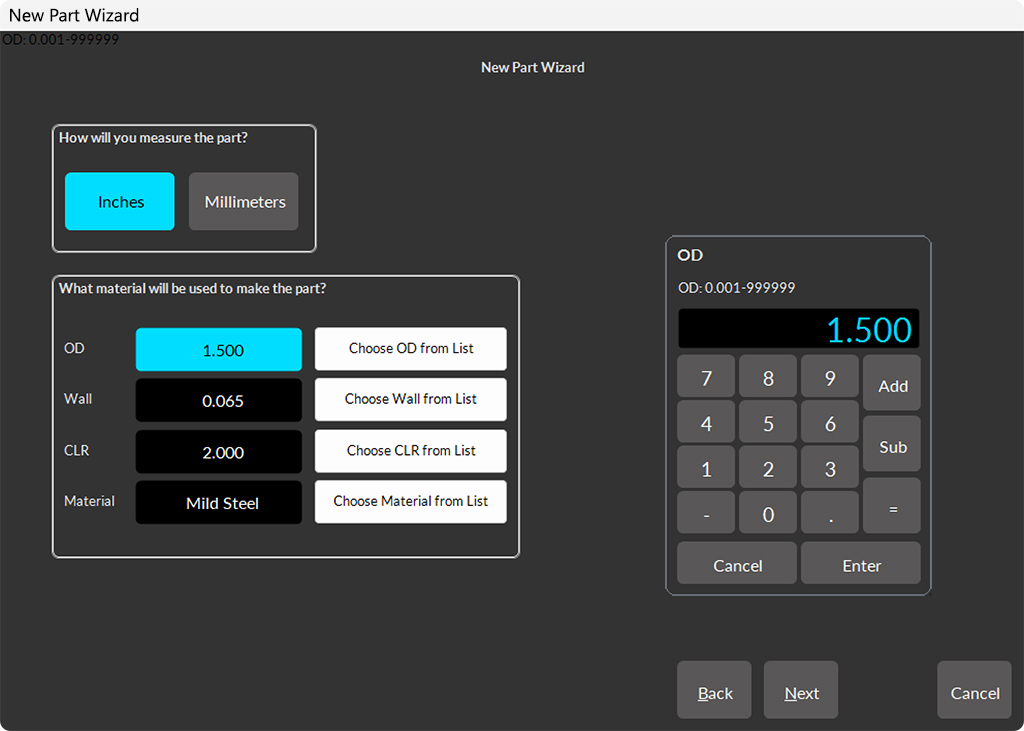

The New Part Wizard walks you through each screen step by step allowing for quick, easy, and error-free creation of new part programs.

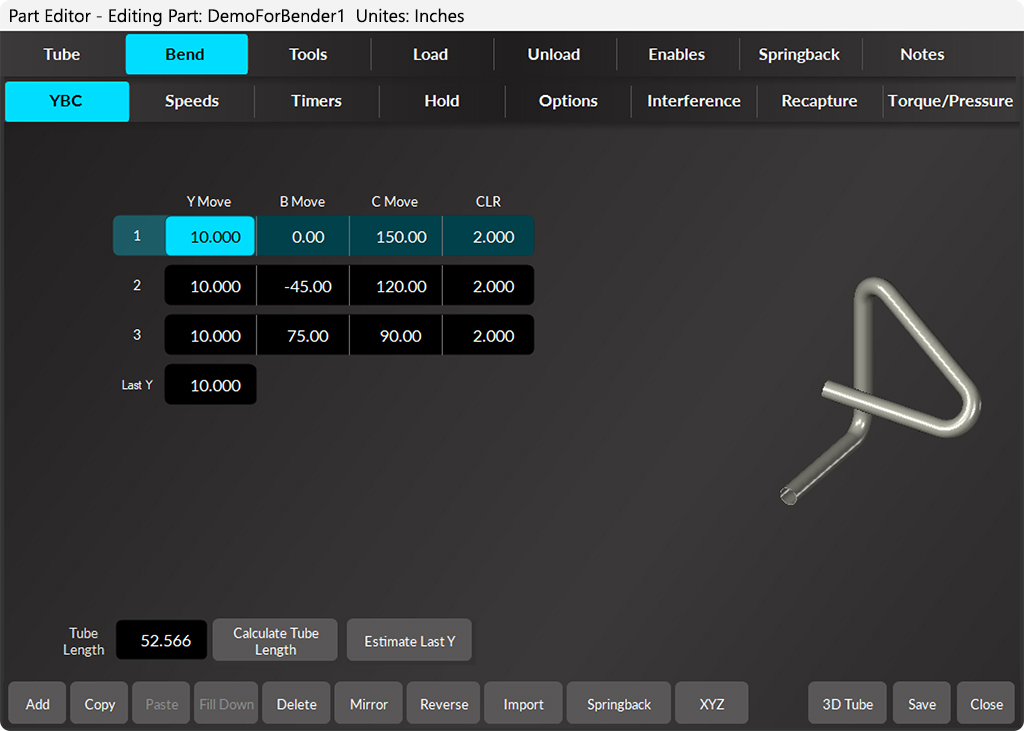

New customers are surprised by how quick and easy it is to program parts in BendPro, especially when compared to other control systems. The Parts Editor is designed to make data entry and editing intuitive and easy.

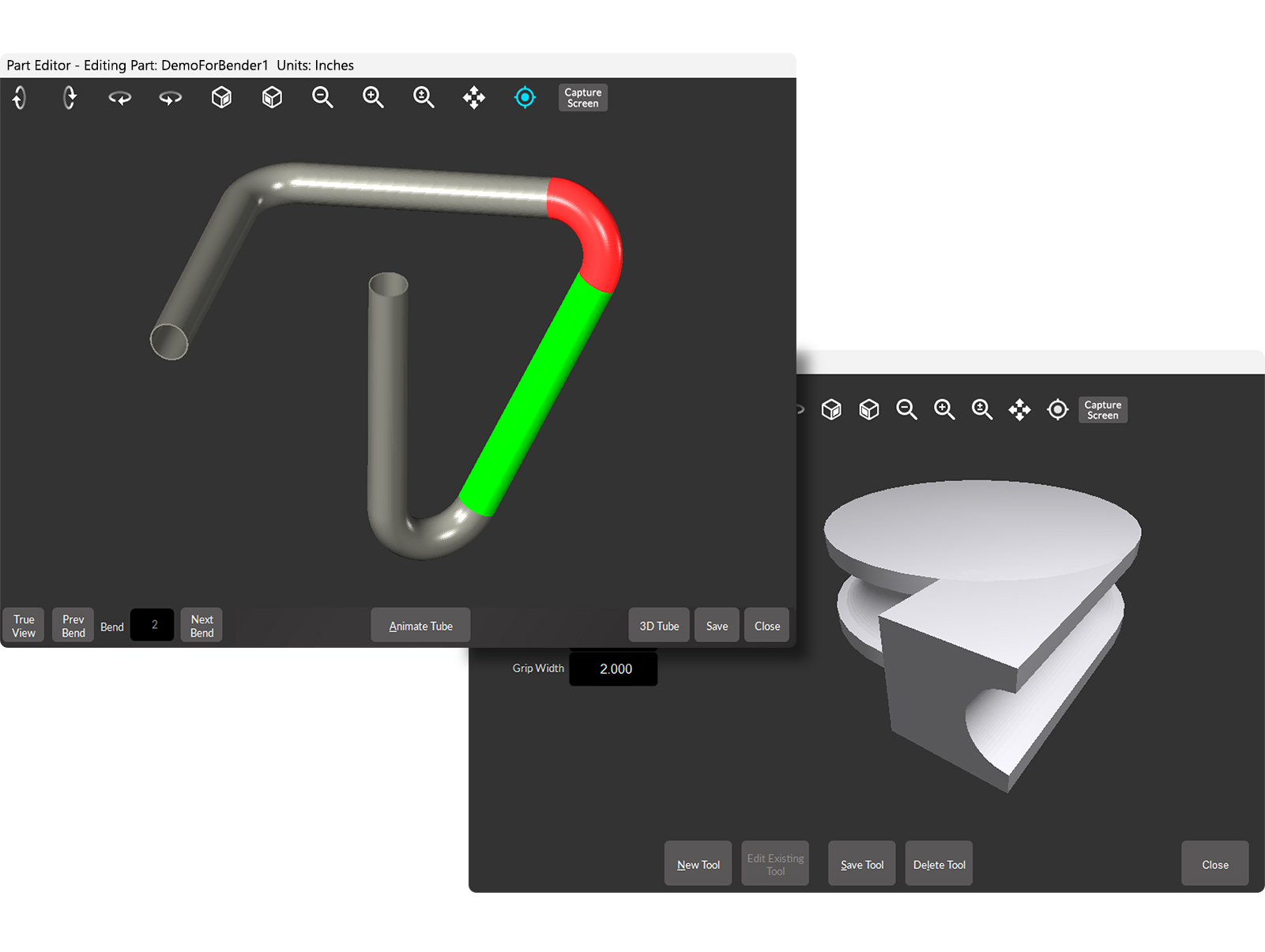

Any programmed part can be displayed in 3D for the purpose of verifying the shape and bending orientation. Command buttons are included for rotating, spinning, panning, zooming, etc. The tube can also be animated to show the bending orientation.

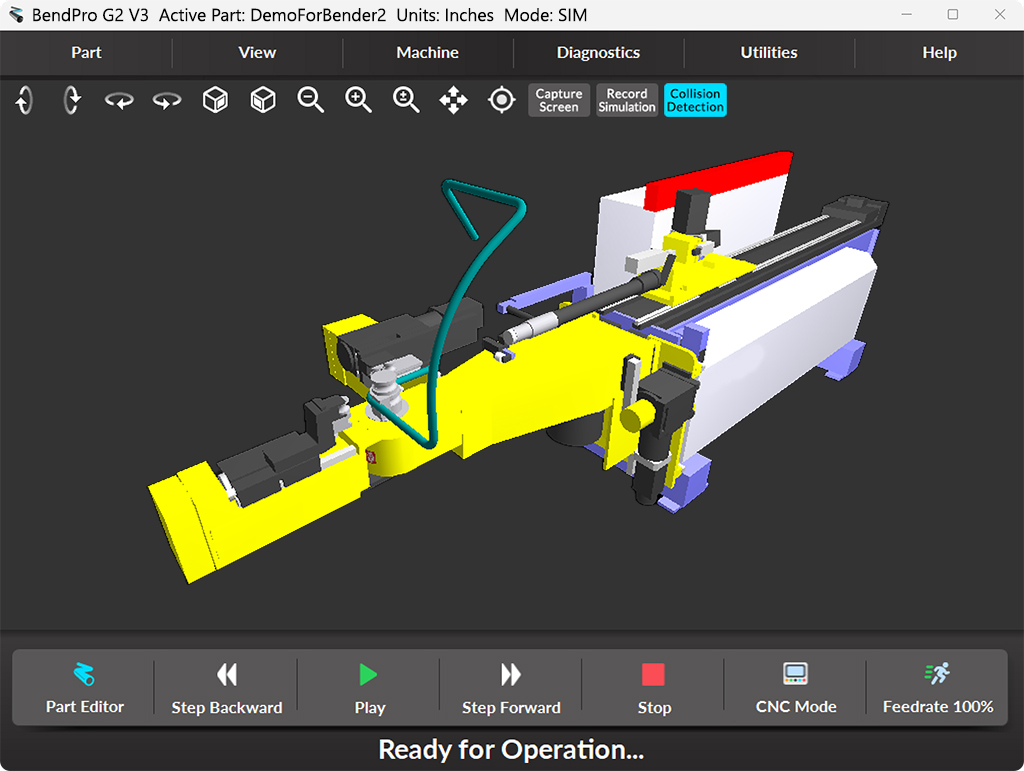

BendPro software has a powerful option called SIM that simulates the bending process to detect potential collisions between the tube, bending machine, and bend tooling.

SIM can also be used to determine optimal bending sequences in order to avoid collisions and also reduce cycle times.

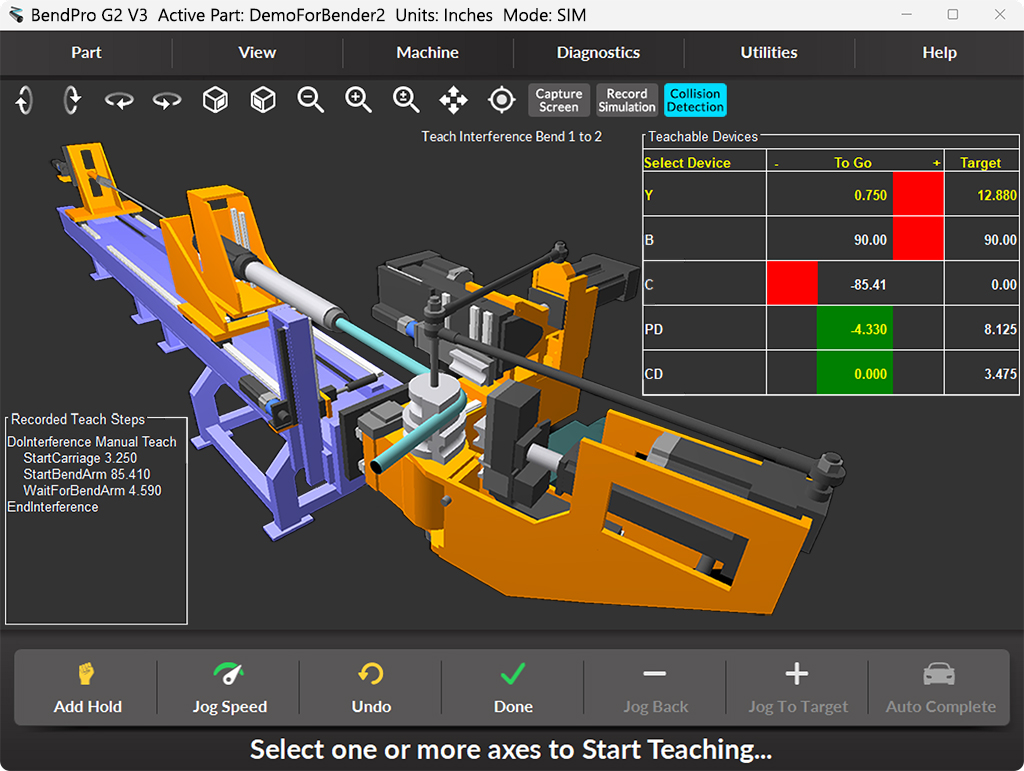

Programming interference moves is often a complicated and time-consuming process with other bender controls. BendPro has several options to make programming avoidance moves quick and easy.

Teach Mode is used for programming avoidance moves and for optimizing bending sequences to increase production.

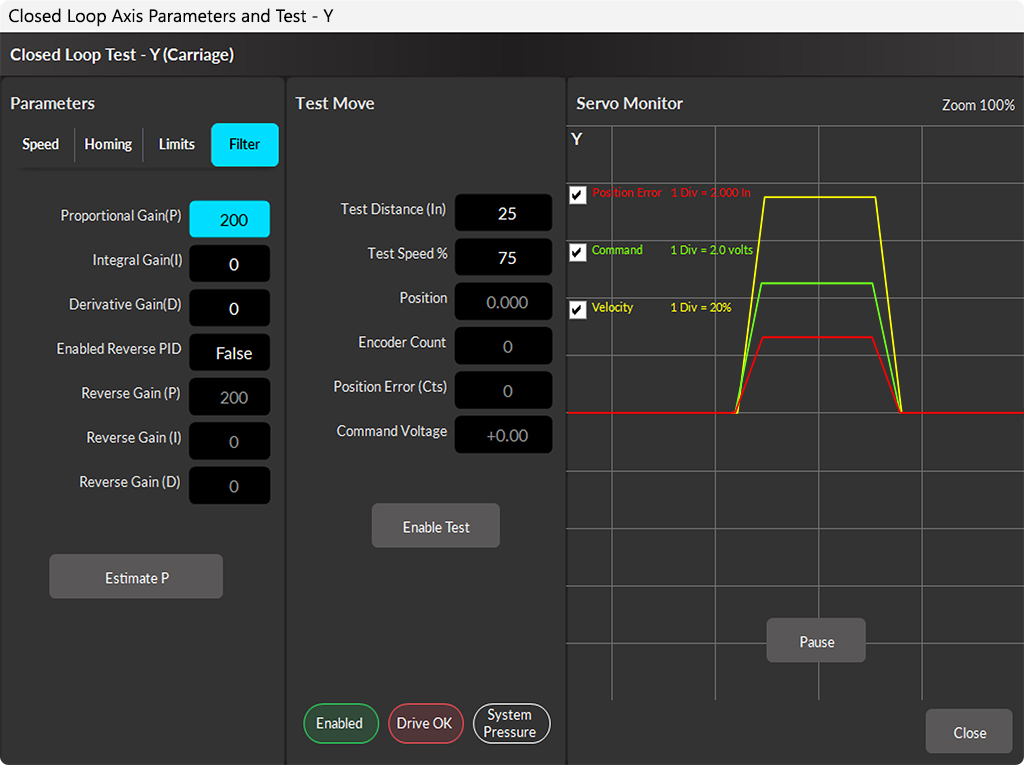

BendPro’s extensive built-in diagnostics can be used for real-time troubleshooting of all machine devices including sensors, valves, and servos.

The Servo Scope can be used to quickly configure and tune servo devices. This powerful tool can also be used to occasionally give your bender an advanced tune-up. This helps increase the speed, accuracy, and repeatability of any servo device including motors, servo valves, and proportional valves.

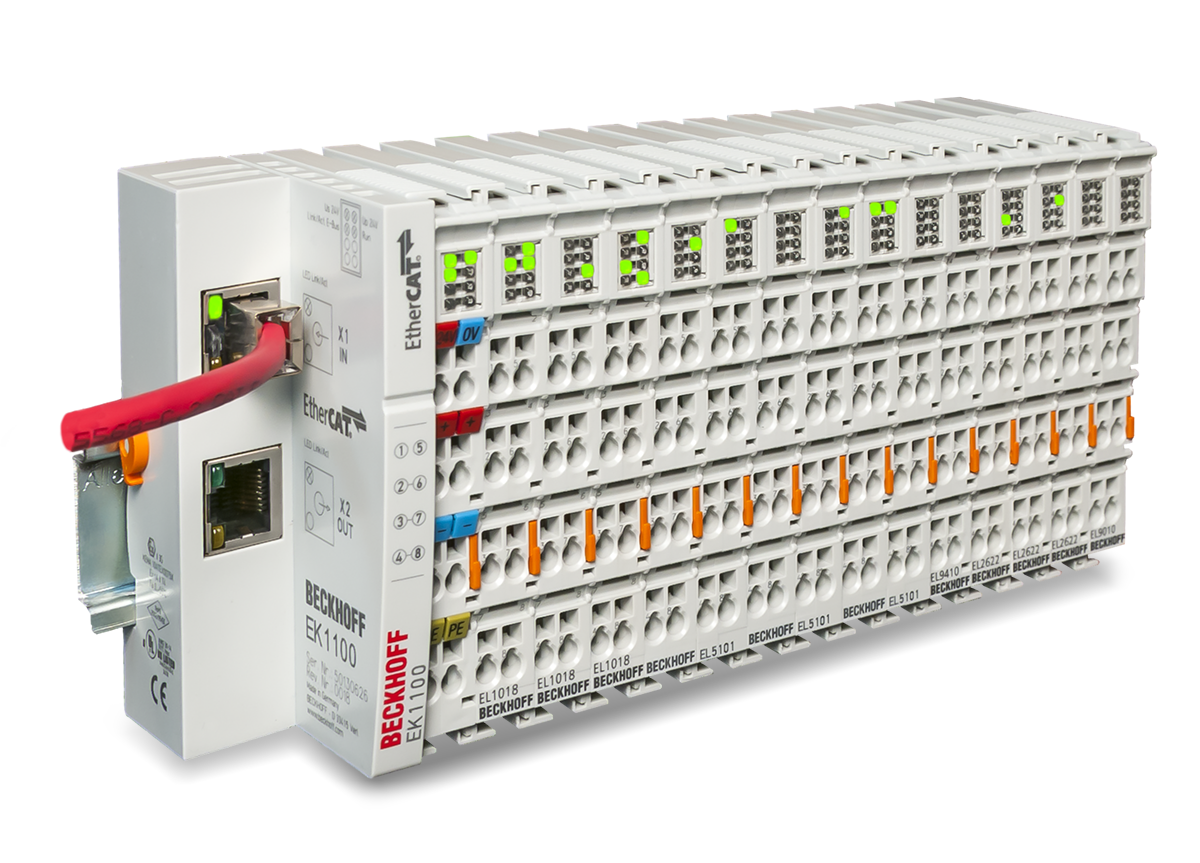

We chose Beckhoff PCs and I/O modules because of their proven track record in industrial environments. Furthermore, the Beckhoff PCs and I/O modules are stocked worldwide and are guaranteed for long-term availability – something you will not get with consumer products such as tablet PCs or Android tablets.

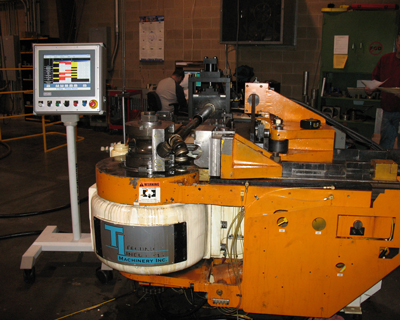

A compact Beckhoff I/O rack mounts inside the bender’s main electrical cabinet and interfaces to sensors, valves, encoders, and servo drives. We use Beckhoff I/O terminals because of their rugged reliability, known performance, and long-term availability.

BendPro’s hardware is of the highest quality, performance, and reliability. The control is housed in a compact, mobile, Rittal operator console with locking casters. The console is connected via high-speed EtherCAT (Ethernet) to a compact I/O system which consumes very little space in the bender’s electrical cabinet. Heavy-duty Allen-Bradley pushbutton switches and joysticks are used for machine operation at the console.

Customers tell us that our technical support is the best in the industry. We have support offices in Colorado and the United Kingdom. We also offer online remote support using popular TeamViewer software, allow us to login to your BendPro G2 control to help quickly diagnose problems, update software, activate new software features, re-tune servo drives, etc.

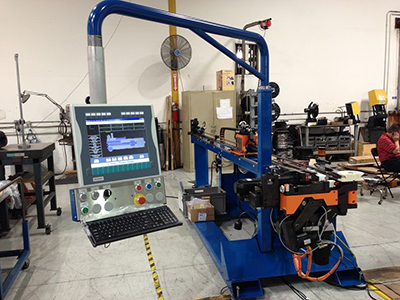

With Digital Servos and 3D Simulation

This Aircraft company is standardizing on BendPro

With Swing Away Wiper Die

Interfaced to Eaton Leonard Vector CMM

With Boost and Tube Cutter

Interfaced to Romer CMM

With Electric Y axis Boost

With Tube Cutter

Ontario Canada

Oxford England

With Boost Clamp and Loader Interface

California

With Servo Pressure Die and Pressure Die Assist

In the Current Tech Lab

Tubecraft in the UK has standardized on BendPro

Interfaced to Romer CMM

With Overhead Clamp

With Programmable Boost direct on tube

With 3D simulation and Collision Detection

Interfaced to Romer Measuring Machine

No. BendPro can be installed on-site at your location. This will save you money on trucking costs and also reduce the amount of time your bender is down.

In some cases, yes. BendPro can import part files from some of the control systems made by Eaton Leonard, Pines, Adaptive Motion, and others.

In most cases, no. BendPro can interface to almost any existing servo system. If your servos are obsolete and/or starting to fail, you might want to consider replacing them. We will quote replacement servos as an option. The servos can also be replaced later if desired.

BendPro was designed to work on any rotary draw, CNC tube bending machines. Companies often standardize on BendPro for this reason; their operators only need to learn a single control system.

The following list includes some of the benders currently supported by BendPro:

Yes. BendPro can control all-electric benders, hydraulic benders, and hybrids.

Benefits include increased performance, reliability, functionality, ease of use, and excellent support by experienced engineers.

Software updates are always available at no charge.

You will have unlimited phone and internet support from experienced engineers at our offices in Denver, Colorado and the UK.

Not everyone needs simulation software. Companies that purchase this option are those that frequently bid on bending new part shapes. They want to make sure they have a bending machine that can produce the part without machine interference. The software also estimates cycle times, which also helps during the bidding process.

Desktop programming and simulation software, as well as interfaces to CAD, CMMs, robots, loaders, unloaders, cells, tube cutters, hole punches, corporate networks, the internet, custom software, etc.

Since 1988. With over 1800 tube bender controls in the field, we are here to stay.